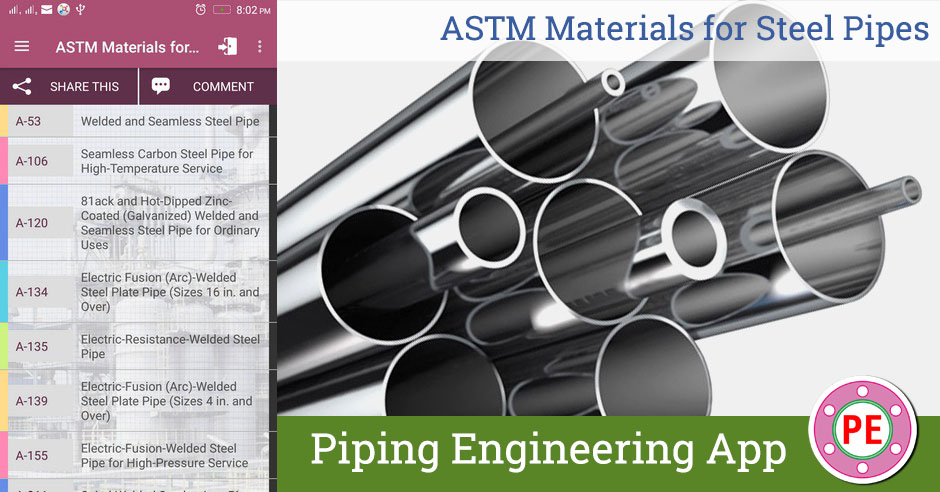

Americal Society for Testing and Materials (ASTM) has researched and defined various material standards for oil and gas industry. Properties of these materials depend on chemical properties of fluids to be handled, design temperatures and pressure as well of method of manufacture of pipe fittings. Pipes in oil and gas industry are made either with seamless process or using plates and welding process. Here is a list of such ASTM Standard materials designed for manufacture of pipes by seamless and welding process.

| Sr. | Number | Title |

| 1 | A-53 | Welded and Seamless Steel Pipe |

| 2 | A-106 | Seamless Carbon Steel Pipe for High-Temperature Service |

| 3 | A-120 | 81ack and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Ordinary Uses |

| 4 | A-134 | Electric Fusion (Arc)-Welded Steel Plate Pipe (Sizes 16 in. and Over) |

| 5 | A-135 | Electric-Resistance-Welded Steel Pipe |

| 6 | A-139 | Electric-Fusion (Arc)-Welded Steel Plate Pipe (Sizes 4 in. and Over) |

| 7 | A-155 | Electric-Fusion-Welded Steel Pipe for High-Pressure Service |

| 8 | A-211 | Spiral-Welded Steel or Iron Pipe |

| 9 | A-312 | Seamless and Welded Austenitic Stainless Steel Pipe |

| 10 | A-333 | Seamless and Welded Steel Pipe for Low Temperature Service |

| 11 | A-335 | Seamless Ferritic Alloy Steel Pipe for High-Temperature Service |

| 12 | A-358 | Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe for High Temperature Service |

| 13 | A-369 | Carbon and Ferritic Alloy Steel Forged and 80red Pipe for High Temperature Service |

| 14 | A-376 | Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service |

| 15 | A-381 | Metal-Arc-Welded Steel Pipe for High-Pressure Transmission Systems |

| 16 | A-405 | Seamless Ferritic Alloy Steel Pipe Specially Heat Treated for High Temperature Service |

| 17 | A-523 | Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High Pressure Pipe-Type Cable Circuits |

| 18 | A-524 | Seamless Carbon Steel Pipe for Process Piping |

| 19 | A-530 | General Requirements for Specialized Carbon and Alloy Steel Pipe |

| 20 | API-5L | Line Pipe |

| 21 | API-5LX | High-Test Line Pipe |

| 22 | API-5LS | Spiral Weld Line Pipe |